Introduction

Every business venture should be sound and secure in order to attain the best out of the enterprise. To do this, a business must be able to achieve the objectives, follow the schedule, formulate strategic schemes and arrangements, and operate the tasks that are carefully laid out during planning. Having a competent, experienced manager is crucial so that all the plans are successfully carried out and excellent quality products and services are offered. This is where the operations management comes into play.

Operations management has many techniques, and to follow these faithfully would ensure auspicious effect to the business venture. Operations management is one of the most important operations in any business enterprise. There are different labels that are closely related with operations management. Some of these names include physical distribution, logistics management, procurement and supply, product flow, supply chain management, and demand chain management. All of which refer to the diverse and dynamic function with vast flexibility to adapt to changes and constraints given by the unpredictable business environment. With these factors, it makes sense to simply the conduct analysis of the operations management process in this way: logistics is the combination of supply, materials, management, and distribution—all functions in the supply chain (Rushton et al., 2006).

This business report will discuss the organization of the supply chain including how to avoid procedures that will impede production. This will also post recommendations on how to address issues that are significant with the business venture being studied. This paper will also discuss the concepts and methods for a productive management of the supply chain and recommend the best organizational structure for the business through improving productivity and measuring the performance of the said supply chain.

Discussion

Supply Chain Strategy

Determining the correct supply chain strategy aids the growth and development of a company. The first thing to do is to ascertain how the business enterprise is going to compete within the market: its resources, capabilities, capital, etc. Though vertical integration may look appropriate for a power tool manufacturing company because this scheme enables more control over the inputs of the production process, the supplies, and the distribution, and improves efficiency, it is not practical to own all production processes. A keiretsu network is helpful to establish greater efficiency by outsourcing some of the minor production processes. Moreover, since this business is eyeing for long-term operation, opting for a virtual company strategy is unwise. Virtual companies only work well with short-term projects and for smaller organizations. Hence, a Keiretsu network is the most suitable supply chain strategy for the proposed power tools manufacturing company.

Keiretsu’s network serves as the core of Japanese corporate networks. The term refers to stable clusters of corporations and financial institutions. It has two main types: horizontal and vertical. Horizontal type includes diverse constellations of large financial institutions, trading companies and manufacturers. On the other hand, vertical type is used by upstream supplier networks and downstream distribution channels of large manufacturing firms. It is basically used by large business groups, conglomerates, and corporations (Whittaker & Cole, 2006). However, a keiretsu network could also be a form of collaboration wherein a part of company purchases form few suppliers and a part implements vertical integration wherein the company develops the ability to produce goods and services previously purchased or to actually buy a supplier or distributor (Heizer & Render, 2001).

According to the investors, they have the capacity to own and operate production facilities and are even willing to consider ownership of any other necessary component of the supply chain. Hence, the type of keiretsu network that partly implements collaboration with few suppliers and partly implements vertical integration. This would allow the company to strengthen its own manufacturing capacity by owning and managing a large part of its production facility. Moreover, outsourcing or buying products and services of other suppliers will lessen the risks for the company and will allow them to produce major parts of the power hand tools it is manufacturing.

Supply Chain Metrics

Performance measurement is defined as a process of quantifying the efficiency and effectiveness of every action in the production process. A performance measure is composed of a set of metrics used to measure efficient of the process. The Supply Chain Operations Reference (SCOR) model was introduced by Supply Chain Council (SCC) to create a prioritized improvement portfolio tied directly to a company’s balance sheet for improving quality performance and profitability. For a power tools manufacturing company being studied whose primary stakeholders are the investors, profitability should dictate much in the performance metric.

For the company, quality should be the primary metric for supply chain performance. Cycle time should be shorter, wastes and defects should be minimized if not completely eliminated, costs should be reduced, and preventive measures should properly be implemented. For the staff, there should be more empowerment, training, and recognition in order to improve their motivation and performance. Lastly, a supply chain strategy should be customer-centered. Hence, its performance could also be measured based on the level of satisfaction that the customers receive from the manufacturer. In the company’s case, it should be able to deliver to retailers’ just-in time new inventories are needed. It should also be able to provide support to customers if ever smaller parts of the tool should be replaced or repair is needed (Zsidisin, 2008).

Zsidisin (2008) also identified useful performance metrics for supply chain management integration as identified by the SCOR. First attribute that the company has to observe is supply chain reliability wherein the supply chain is able to deliver the right product at the right time, place with proper documentation to the correct customer. A strategic metric to measure this attribute is Perfect Order Fulfillment Form.

The supply chain responsiveness or speed at which supply chain is able to provide product to customer could be measured by Order Fulfillment Cycle Time. There is also supply chain agility wherein the supply chain is able to respond to market place changes to gain or maintain competitive advantage. This could be measured by the following metrics: upside supply chain flexibility, upside supply chain adaptability, and downside supply chain adaptability (Chandra & Grabis, 2007).

Supply chain costs or the costs associated with supply chain operations could be measured through Supply Chain Management vis-à-vis Cost of Goods Sold. Lastly, Supply Chain Asset Management or the effectiveness of the company to manage assets in order to maintain demand satisfaction is measured by the following metrics: cash-to-cash cycle time, return on supply chain fixed assets, and return on working capital. All of these metrics reflect the performance of supply chain integration management because each gives information about maintaining quality management in relation to company’s asset, costs, production performance, delivery performance, and financial status.

Supply Chain Issues

Supply chain management implementers experience various issues and challenges when integrating supply chain strategies with the overall corporate business strategy. One the most common issue in the supply chain is local optimization. Local optimization refers when members of the supply chain make decision based on the needs of the final user of the supply chain without having limited or no information about the conditions of the retailers. Distributor and manufacturers over react on fear that retail customers will run out of products hence large orders are places creating excessive inventories in the distributors or the manufacturer. At the same time, when sales at the retailers slow down, distributors and manufacturers over react by cutting order as the don’t want a over inventory problem (Chan & Kumar, 2009).

The effects of local optimization are obvious; too much inventory causes inefficiencies in production for the manufacturer resulting in higher cost in the production line. In the distributor it causes high storage cost deterioration of the products, increase in labor, and the risk of facing shifts in the demand. On the whole, in an integrated chain, there is always a deliberate attempt to maximize local returns while decreasing currents costs due to acute awareness. Because of this and the need to minimize losses, whenever there is slight increment in demand overcompensation is guaranteed. Likewise, should there be slight downturns, then similar overcompensation takes place for the simple reason that the business should not be left holding on surplus inventory. No wonder, fluctuations are often more highlighted (Chan & Kumar, 2009). For these reasons, the immediate response that distributors often take to huge orders is compensation with even a larger volume demand from producers in the thinking that retail sales will increase.

Sales Incentives, quantity discount, quotas and promotions all have an affects the supply chain. When incentives are introduces in the supply chain it creates fluctuations in inventories resulting in higher costs throughout the entire supply chain. Incentives must be aligned within the supply chain to avoid shortage that will cause loss of sales or overstock of raw materials in manufacturers. Broadly speaking, incentives often make businesses to get involved in chain for sales that are yet to materialize. The effect of this is fluctuations which are costly to everyone in the supply chain.

Then there is the issue of Bullwhip Effect. By definition, this refers to the increasing fluctuation in orders that usually occur when orders move through the supply chain—from retailers, to distributors, to wholesalers, to manufacturers. The fluctuations in this context usually increasingly take place every step of the way. The effects of this are obvious: it increases all the costs related to transport, shipping, reception and inventory. On the other hand it diminishes issues related to customer service and probability of profitable returns. Therefore, the bullwhip effect occurrence can be when there is a decrease or increase in orders. One of the ways through which bullwhip effect can be reduced and therefore improve opportunities across the supply chain is application of Lot Size Reduction. This entails aggressive management including development of cost-effective shipment of reduced truckload, provision of discounts on the basis of yearly volume and not on the basis of individual shipments, and decreasing the cost relating to making orders including use of standing orders and application of e-purchasing strategies. All these bring in the issues of discounts and quotas. In fact, the easiest way to controlling the bullwhip effect which is brought about by forward buying is the reduction of the number and levels of wholesale price in terms of discounts(Chan & Kumar, 2009).

The second issue in the supply chain is deciding whether to outsource supplies or have a disconnected supply network. This means relying on the company’s own technology to produce its products or having a strategic partnering with others. This issue deals with supply contracts wherein prices, delivery lead times, return policies, the influence of Internet in procurement process, and quality standards which are mutually agreed by the purchaser and external supplier. The management decides what products to produce internally and what products that should be bought from external sources considering the available resources and level of competition in the market.

The third issue is distribution strategies. This deals with the movement of goods within the supply chain. The management may opt to select delivering its products through direct shipment, load consolidation, or cross-docking which involves transshipment. This issue is crucial because lead times and transportation costs are at stake when products are held in abeyance pending delivery. It also affects the ability of the company to replenish products while waiting for the previous delivery to be completely done. In this is the issue of marketing distribution model.

The distribution marketing models refers to the different channels that need to be employed in business in order to identify the consumers and how best they could be reached with supply chain chosen. This model is best dealt with through market research in order to identify the consumer needs and analyze the available competition in the market. Relevant technologies are then designed in order to meet identified customer needs various distribution strategies such as use of brokers and retailers. Both indirect and direct marketing distribution channels are at times employed. Distribution channels are normally aligned to the customer pattern in different regions (Coyle, 2008). Local distribution channels are normally planned differently compared to the international channels which are normally planned based on the probability of success. At times the scope of distribution is limited to a single intermediary in a given territory. Proper marketing distribution model normally result into wider customer base, better market coverage, an increased level of sales and at times higher rates of impulse buying.

Concepts and Methods

Managers of manufacturing companies are confronted with an array of new systems that are supposed to improve production efficiency and supply chain management integration. Like all other business processes, choosing the best technique for supply chain management requires making trade-offs, planning, and thorough preparation before implementation. From the above identified issues, there are some key concepts that must be understood by the company in order to address each issue. One of them is that marketing programs should ensure that all organs of the business are properly aligned to the needs of both the business organization and the target customers. Marketing programs should always be integrated to the entire business operations so as to ensure that customers receive the greatest value possible for their products and services. A detailed program on supporting the marketing efforts, efforts to ensure efficiency and effectiveness in the marketing process and ensuring that the best means of marketing are employed should all be enforced. This marketing process entails ensuring that the marketing process is categorized into four major groups. The products and services, their prices, the place where the marketing would be done and the overall promotion process are integrated in order to ensure that the customers get very superior value from the organization (Coyle, 2008).

With regard to the issue of distribution network configuration, the management must understand joint-location inventory management system wherein there is created a central warehouse for a particular region. This central warehouse, aside from other component warehouses, aims to provide a single warehouse unit for each region to allow the company in releasing much capital for the construction of warehouses. Delivery points are integrated according to their proximity to the central warehouse and a particular route is established between those points (Farahani, Rezapour & Kardar, 2007).

The company must also have a balance of inbound and outbound flow in its distribution channels. Inbound logistics means the receipt and storage of raw materials for manufacturing process, while outbound logistics deals with the storage and distribution of finished products (Coyle, 2008). These two must be balanced heavy inbound flow requires detailed scheduling and monitoring to ensure that parts arrive when needed. Heavy outbound flow on the other hand, requires bigger storage capacity and greater storage costs.

For the procurement strategy, the company must understand that this is a complex decision to make as it requires that the procurement decision be incorporated in the company portfolio to have a better overview on how to balance the costs and benefits of internal production and external outsourcing. The fundamental questions that the company must consider are the number of supplier to retain and how they will be chosen. The company may also opt to adopt procurement software and Internet portals (Chandra & Grabis, 2007).

In managing the distribution strategy issue, the management must balance the trade-offs between outsourcing and buying; and it is incumbent upon the supply chain players to provide each other with the necessary information regarding prices, profit margins, warranties, and so on. The company can utilize network algorithms which utilize linear and nonlinear programming techniques. This process allows the company to have a better estimation of the distance between warehouse locations and points of delivery and time spent for each delivery, thereby assisting it to determine other shorter and inexpensive delivery routes (Chandra & Grabis, 2007).

Other general terms the company must be acquainted with are JIT, TQM, MRP II, and ERP. Just in Time (JIT) operation is an additional component of Time-based Competition (TBC). The operation begins when an order from a customer is made and the supplying centers work to meet this order. JIT calls for subassemblies, produce the components, and deliver products where they are needed just in time. Thus, it is a company-wide philosophy towards eliminating waste in all operations of the company and improving materials throughout. Thus, the ultimate goal of JIT is to serve the customer with higher levels of quality product and service (Bateman & Snell, 2004).

JIT is implemented through various key production concepts which originated from Japan’s Toyota Motor Corporation. This includes the following concepts (Bateman & Snell, 2004):

- Elimination of Waste- This involves elimination of waste of time, people, machinery, space, and materials.

- Perfect Quality- This includes production of perfect parts, size reduction, and production of the product at exact quantity needed.

- Reduced cycle times- This involves accomplishment of entire manufacturing process rapidly and to reduce time spent on doing the parts.

- Employee involvement- This serves as the central concept for success.

- Value-added manufacturing– This is to further add value to the finished product.

- Discovery of Problems and prevention of recurrence- This include fool-proofing and falsifying.

For effective management in an integrated supply chain, the Just-in-time (JIT) system eliminates requiring to examine, to forward, and to file the inbound material inspection. It allows a quick response undertaken by manufacturers and retailers. Using this system, suppliers are only paid for the number of components that are used for a period’s production runs (Piller, 2005). Team learning, personal mastery, systems thinking, building a shared vision, and mental models are the five rudimentary disciplines that every organization should possess (Coyle, 2008).

For the power tools manufacturing company, JIT is useful because JIT can improve the supply chain performance metrics identified by the SCOR model and other metrics and issues addressed earlier in this report.

TQM is another useful principle that the power tools manufacturing company could implement. Total Quality Management (TQM) is a “comprehensive approach to improving product quality and customer satisfaction” (Bateman & Snell, 2004, p. 205). This strategy of TQM is characterized by being customer-oriented and organized works of the company. One of the immediate actions of this strategy is to reorient managers to involve more of their people towards improvement of all aspects of the business. Continuous improvement should promote group problem solving, information sharing, and cooperation within any business functions. Thus, for TQM, quality would mean “meeting or exceeding the requirements, expectations, and needs of customers” (Bateman & Snell, 2004, p. 205). These needs also include those which are not articulated by the customers. In a rather general perspective, TQM implies excellence throughout the company’s total system, design production, distribution, service, and the involvement of all categories of employees, customers, and suppliers in the quality service.

Another key concept for efficient supply chain management integration is MRP II. MRP II is a comprehensive system for planning and scheduling all the resources of a manufacturing company. It provides an extensive control loop in the manufacturing and material planning. It is extensive and starts as early as the business plan which expresses company objectives in terms of projected sales, incomes, costs, and profits. This process is usually referred to as “push system” since each work order is tracked through a series of work centers (Coyle, 2008).

MRP also extends to supply chain giving highly efficient, integrated operations. MRP is a dependent demand method that finds demand for materials directly from master schedule (Chandra & Grabis, 2007). MRP provides the opportunity earlier purchase settings. This process often has the assumption that irregular demand tries to realize zero stock-outs and tailors on prioritization. MRP implies that a demand predictions is devoid of error is availed and all bills relating to the product is not with error.

Lastly, there is ERP. Enterprise resource planning (ERP) software is a tool that processes transactions while providing enterprise-wide data base. ERP served as the product of tactical and strategic transformation of supply chain management. Fast delivery and access to information for employees was increasing. Hence, the companies needed to provide information for their employers. They needed to do a database specially made for the needs of their own enterprise; hence, the birth of enterprise resource planning. ERP has also replaced information system in its functions such as operations, finance, marketing, engineering, procurement and other retail industry functions (Rushton et al., 2006).

Process and Control Risks

Process risks pertain to risks within the organization’s internal supply chain which typically includes design, manufacturing, and distribution. For the company, one significant process risk could excess inventory which could harm its financial performance. The extent of risk stemming from the inventory depends on the value of product, rate of obsolescence, and uncertainty of demand or supply (Sodhi & Tang, 2012). We know for a fact that power hand tools have relatively lower value compared to high-tech construction tools. Likewise, its obsolescence is high given with the fast-paced changes in technology nowadays. There are various high-end construction tools and equipment available in the market today. Likewise, once a customer purchases a power hand tool, the tool can last for at least five to ten years. He could not be expected to buy a new set of hand drills if the one he has is still working. Therefore, the demand is uncertain. Managers can use these three approaches to mitigate effects of such risks: pooling inventory; creating common components across the products, and postponing last stages of production until receipt of orders.

On the other hand, control risks may include internal control systems, rules or policies that are observed to have counter-productive results for the company. A significant control risk for the company is implementing TQM principle. There is a consensus in the literature that companies now tend to shift to TQM to assure quality within the entire business operation. Nonetheless, companies, having different quality assurance processes, cannot haphazardly shift to implementing TQM. Many companies have reported problems such as excessive downturn in production, resistance from people, and many others. There should be adequate planning, preparation, and strategies in order to achieve maximized benefits of TQM (Rushton et al, 2006).

Environmental risks are external, oftentimes weather conditions that a business venture could not control. This includes flood, hurricanes, earthquake, tsunami, fire, and the like. In case of environmental risk, the company is vulnerable to any weather condition that could impede its operations. For example, since the main distribution system of the company is trucking, its operation is vulnerable to floods. Hence, the company’s trucking facilities should always be ready to seek for alternative routes just in case trucking ways are affected by transportation disruption.

Organizational Structure and Organizational Components

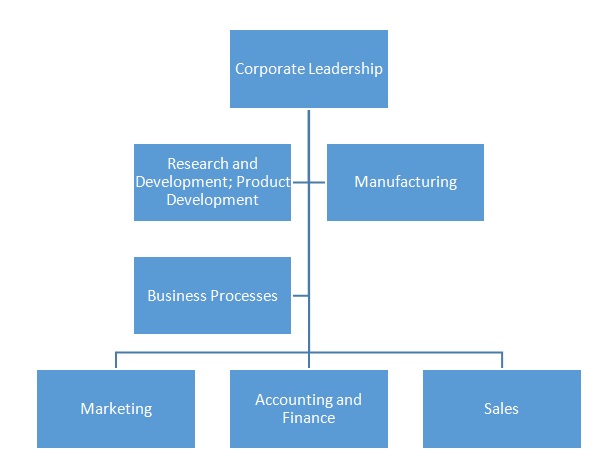

For manufacturing and marketing power hand tools, it is best to adapt a centralized form of organization structure. First, the company can reduce costs when there is centralized decision making. Second, centralization is an opportunity to have the best people makes the decision making for the company increasing its productivity (Weitz, 2009). Finally, centralization increases efficiency (Koren, 2010). The three components that should be included in the organizational structure are product development, business model, and manufacturing process. Koren (2010) says that these three are interdependent due to globalization. A company will not succeed if it has good business model but does not have the correct product to sell. Even if the company has the right product, it will still fail if it does not develop its product cost-effectively. In turn, a company will only succeed if it has good manufacturing aspect and good business model. A recommended organizational chart could be:

The manufacturing block of the organizational chart includes different work stations including procurement, logistics (from outsourcers), production, packaging, and delivery. Procurement section is closely linked to product development department because it identifies which raw materials are necessary for production. In turn, the production section works closely with research and development which identifies the most efficient and appropriate techniques for assembly of tools, production of blades, electric circuits and other components of the power hand tools. Logistics section should be well-coordinated with suppliers and outsources of the minor parts such as handles. It needs to ensure that all supplies will be delivered just-in-time these are needed. It should ensure that failure to deliver will not cause hiccups or hindrance to production of the company.

A sub-section called assembly in the packaging section will deal with assembly of major parts produced in the company and the minor parts produced by outsources. The packaging section will handle final quality check and packaging of all the tools produced. Quality control includes testing all of the products if each passes quality standards as identified by the company. All defective products should be brought back to production or assembly depending on which part does not pass quality check. Tools that pass quality check will pursue to packaging. Delivery section will work closely to the sales department because it will transport finished products to all selling points. A representative from the sales section should go with the delivery personnel in order to satisfy all of the sales form required.

Strategic Operations Management and Mass Customization

Strategic management aims to assess a company’s strengths, weaknesses, opportunities and threats, provide vision statement which is translated into organizational goals, and formulate strategies to achieve such goals. The company must ensure that they employ skilled personnel, they do the right things, they satisfy the needs of the consumers, and they fulfill the operations required to meet financial goals of the company.

Operations management includes combination of supply, materials, management, and distribution. There are ten operations management decisions that the company needs to do including: quality management, product design, supply chain management, human resources, location, capacity design, lay-out, scheduling, inventory management, and maintenance.

Quality should be one of the primary goals of any company. They exert considerable time and resources to ensure quality in every aspect of business operations. Failure to achieve quality can cause adverse and critical implications to the performance of the entire firm. Importance of quality and conformance to standards of acceptable quality increased tremendously in the recent yeas. Now, customers demand high quality and value. Any less than these demands shall have adverse impact on customer satisfaction. Hence, quality is an important asset and companies strive hard to implement quality control and management. Product design should be well-thought of the research and development department and the production department. These departments should coordinate in making this decision (Chandra & Grabis, 2007).

Supply chain management integration should be the effort of all internal and external value chain of the company. Human resources and location decisions of operations management should be lead by corporate leadership. Human resources should be aware of the principles and overall goal and strategy of the company. Location should be selected with very high consideration of supply chain management, availability of supplies, and logistics. All other management decisions: capacity, scheduling, inventory management, and maintenance are the responsibility of the manufacturing block of the organizational hierarchy. However, it should also be supported by corporate leadership, sales, and human resources.

Mass customization depends on the peripherals of the product. It has been recognized to have positive results based on empirical and theoretical studies for years and many companies are adopting this model successfully (Piller, 2005). This type of manufacturing strategy is highly recommended in the type of business done by the company in this case. Power hand tools are easy to be customized as their parts are interchangeable. The company could seek other means for mass customization such as using the same type of blades, handles, packaging, and the like (Chandra & Grabis, 2007).

Manufacturing Facility and Supply Chain

Globalization in the 21st century resulted to increased competition for modern manufacturing enterprises. The rapid industrial growth in the past few decades has also completely revolutionized older manufacturing strategies. Leagile manufacturing emerged from the concepts of lean and agile principles. There are more specific and more in-depth strategies such as Manufacturing Resource Planning (MRP) and Just-in-Time (JIT) which are more specific and built upon the actual organizational culture of the company. These new strategies enable enterprises to survive the fierce competition. The requirement for faster delivery within the due date, the ability to be flexible to fluctuations in demand and to meet customer expectations are just some of the prime motivators for the company to look for best strategies to improve their daily manufacturing practices (Chan & Kumar, 2009).

Managers of manufacturing companies are confronted with an array of new systems that are supposed to improve production efficiency. Akin to many business processes, the process of deciding the best operations management methods needs planning prior to implementation. MRP provides an opportunity for an out of the ordinary planning in terms of middle level-inventory and companies producing are volumes. However, it also requires minimal flexibility and formality. On the other hand, Just-in-Time (JIT) keeps inventory costs down but it also requires well-structured supply lines and very cooperative workers (Rushton et al., 2006). These two strategies, when properly embedded into the supply chain strategy of the company, could effectively reduce costs for supply chain.

Conclusion

For the company in this case, the suitable supply chain strategy, management issues, risks and risk management, mass customization, cost-reduction and all other identified concerns of investors are addressed. Manufacturing companies spend billions of dollars every year to address problems such as failed product tests, poor supplier quality, poor manufacturing quality, and poor product reliability. Hence, to avoid additional and unnecessary costs and with the help of emerging technologies, firms strive harder towards quality assurance, control, and management. These factors are addressed in this report.

References

Bateman, T. & Snell, S. (2010). Management: Leading and Collaborating in the Competitive World. New York: McGraw-Hill.

Chan, F. & Kumar, V. (2009). Performance Optimization of a Legality Inspired Supply Chain Model: A CFGTSA Algorithm Based Approach, International Journal of Production Research, 47(3), 777-799.

Chandra, C. & Grabis, J. (2007). Supply Chain Configuration: Concepts, Solutions And Applications. New York: Springer.

Coyle, J., Langley, C., Gibson, B., Novack, R., & Bardi, E. (2008). Supply Chain Management: A Logistics Perspective. (8th edn.). Cincinnati, OH: South-Western College Pub.

Farahani, R., Rezapour, S. & Kardar, L. (2011). Logistics Operations and Management: Concepts and Models. New York: Elsevier.

Heizer, J. & Render, B. (2001). Operations Management (6th edition). Upper Saddle River: Prentice Hall.

Koren, Y. (2010). The Global Manufacturing Revolution: Product-Processes-Business Integration and Reconfigurable Systems. Hoboke, New Jersey: John Wiley and Sons, Inc.

Piller, F. (2005). Mass Customization: Reflections on the State of the Concept. Web.

Rushton, A. Terrick, C, & Ugo, W (2006). The Handbook of Logistics Distribution management. London: Kogan Pages.

Sodhi, M. & Tang, S. (2012). Managing Supply Chain Risk. New York: Springer Science LLC.

Weitz, L. (2009). Retailing Management. New York: McGraw-Hill/Irwin.

Whittaker, H. & Cole, E. (2006). Recovering from Success: Innovation and Technology Management in Japan. New York: Oxford University Press.

Zsidisin, G. (2008). Supply Chain Risk: A Handbook of Assessment, Management, and Performance. New York: Springer.