Introduction

The Coca-Cola drink has a rich history and is currently considered as the most popular and the top-selling soft drink in the world not only because of its taste but also recognisable brand affiliation. Dr. John S. Pemberton originally created the drink in 1886 in Atlanta, Georgia. Pemberton worked at Jacob’s Pharmacy where the Coca-Cola syrup was mixed with carbonated water and sold as a refreshing beverage. According to the product description provided on the Coca-Cola Company website, the drink got patented in 1887 and trademarked in 1893 and by the year 1895, it was sold in every U.S. state (Coca-Cola, 2016). The product’s first operations associated with franchising began in 1899 when the Coca-Cola Company started selling franchises for the beverage’s bottling across the entire country while international operations expanded around 1906 (Coca-Cola, 2016).

The Coca-Cola drink was chosen for a close analysis in the paper on operations and supply management because of its significance to the global retail industry. The trademark is one of the most recognisable in the world because of the idea to sell franchises to producing Coca-Cola beverages to partners worldwide. In addition, the company’s operations and supply management are unique because there is a clear divide between suppliers, the Coca-Cola Company and its customers. Therefore, it can be interesting to explore how the company established a supply chain that helps it to maintain long-term success. In the paper, Coca-Cola’s supply chain will be examined, and explanation of different organisations involved in the supply process will be provided, an evaluation of the operations management’s effectiveness in meeting customer demand will be included, as well as recommendations for improvement will be mentioned.

Supply Chain

Suppliers

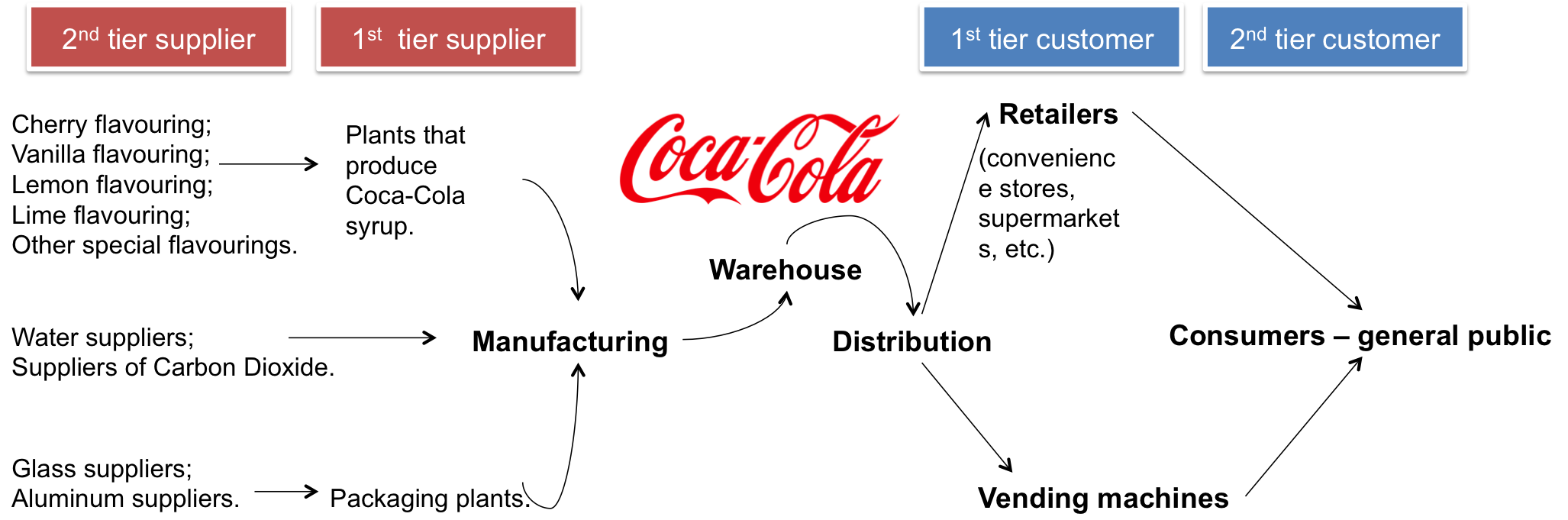

At the present moment, Coca-Cola beverages are produced in more than two hundred countries worldwide, which implies that the company has taken care to establish an effective supply chain system to ensure smooth production and distribution. For the company, water is the main ingredient necessary for the production of carbonated and flavoured beverages. While Coca-Cola does not disclose locations of all water sources that supply the company with water, it is known that they are situated worldwide to account for the fact that its first-tier suppliers are also located worldwide. At the moment, the company has invested into a new corporate water strategy targeted at “reducing, recycling and replenishing the water the company uses to make its beverages” by 2020 (Thorpe, 2011, para. 1). It should be mentioned that the company has strict standards associated with the production of ingredients and requires suppliers to follow all certification practices.

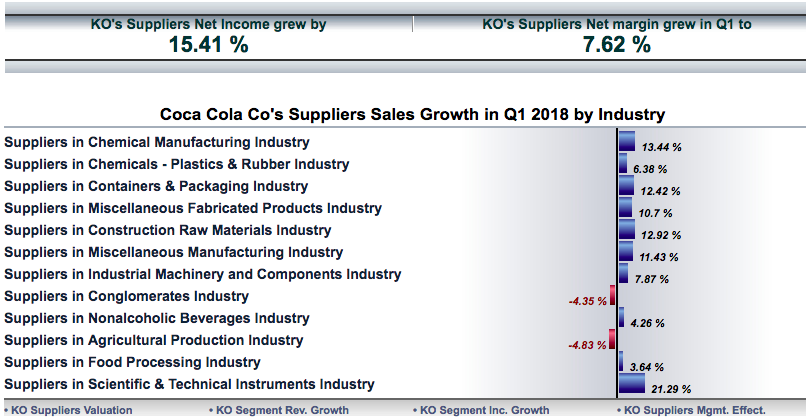

Based on the reported data on Coca-Cola Company’s supplier performance, supplies in scientific and technical instruments industry are the highest performing, with 21.29% sales growth in the first quarter of 2018 (CSI Market, 2018a). Suppliers in chemical manufacturing are second-ranked in performance, with 13.44% sales growth, followed by suppliers in construction raw materials industry, suppliers in containers and packaging industry, and suppliers in miscellaneous manufacturing industry, with 12.92%, 12.42%, and 11.43% sales growth respectively (Figure 2) (CSI Market, 2018a). The poorest-performing suppliers that collaborate with Coca-Cola Company, suppliers in agricultural production and conglomerates industry were identified, with -4.83% and -4.35% sales growth respectively (CSI Market, 2018a).

On a global scale, the Coca-Cola system of operations has more than nine hundred manufacturing and bottling facilities that take a crucial part in the release of carbonated beverages (Coca-Cola, 2012). For ensuring the efficiency of the supply chain, Coca-Cola has reported reducing its waste and emissions through fixing problems such as leaks, uninsulated pipelines, high temperatures, and unnecessary energy consumption.

In 2009, Coca-Cola Hellenic, one of the biggest bottlers of beverages, facilitated the creation of fifteen cogeneration facilities in twelve countries, including EU member-states. Hellenic is an important player in the company’s supply chain because it produces and distributes more than two billion unit cases of Coca-Cola annually (Coca-Cola Hellenic, no date). The organisation of Hellenic’s supply chain is developed in such a way that it manages all relevant procedures associated with manufacturing, planning, procurement, engineering, as well as sustainability. As mentioned in their report on supply chains, Coca-Cola Hellenic is continuously working on quality improvement and assurance of food safety, and enforces high standards on both first- and second-tier suppliers. For instance, the organisation demands that their first-tier suppliers get ISO 9001 (quality) certification, as well as ISO 14001 (environment), and OHSAS 18001 (health and safety) standardisation (Coca-Cola Hellenic, no date). Second-tier suppliers that deal with the provision of packaging and beverage ingredients are required to be certified at a high level: FSSC 22000 standards of food safety and Global Food Safety Initiative.

Europe-Based Operations: Manufacturing

Since Coca-Cola has operations around the world, focusing on a specific territory is important because it will show how the company manages its supply chain within a smaller region. On the European scale, Coca-Cola Enterprises buys beverage concentrates from the Coca-Cola Company uses other ingredients such as carbonated water to create the final product – the Coke drink. Major operation hubs are located in the United Kingdom, Belgium, France, the Netherlands, Luxembourg, Sweden, and Norway (Sapardanis, no date). It is important to mention that in 2010, Coca-Cola Enterprises sold its North American operations to focus on European production. The company acquired bottling rights for Norway and Sweden thus expanding its operations on the European scale. This was done to create a set of consistent processes and standards necessary for acquiring and integrating new territories into the company’s operations. Focusing on Europe made it possible for Coca-Cola Enterprises to put its practices on high quality in place within a short timeframe.

Regarding the optimisation of the European supply chain for Coca-Cola Enterprises (CCE), the company is continuously working on updating existing solutions in all seventeen plants located in the region. New solutions are generally applied to achieve higher automation of processes and improve required sets of skills for making sure that products are deployed at high speed. To keep up with such developments, Coca-Cola Enterprises needed to obtain a partner that could facilitate the transformation of the supply chain. Apart from delivering technological solutions, Coca-Cola partners may help to train employees in the completion of new processes for ensuring the realisation of benefits (Sapardanis, no date).

Computer Sciences Corporation (CSC) was chosen by CCE as the key partner in supply chain optimisation because the company was successful in combining a significant transformation of the ‘front office’ alongside with improving technology delivery capabilities in the ‘back office’ (Sapardanis, no date). These transformations were included in the Genesis program that CCE wanted to implement to maintain its favorable reputation as a leading Coca-Cola bottler in Europe. The Genesys program implemented in all EU locations of CCE (including the United Kingdom) has been set to replace the outdated system in processes such as “order to cash, requisition to payment, and record to report” (Sapardanis, no date, para. 12).

The new program will allow Coca-Cola Enterprises to shorten the time necessary for the completion of the mentioned processes to be more productive as well as to deliver greater visibility in the process of decision-making (White, 2015). CCE positions itself as a shelf-replenishment, supply chain, and sales and customer services company, which means that investing in the integration of effective manufacturing processes that lead all the way up to stocking shelves at local grocery stores.

Distribution

Coca-Cola’s distribution strategy has been developing for decades in order to align with the framework of unique relationships between suppliers, manufacturers, and customers. All bottling partners that operate on a location-specific basis cooperate with restaurants, convenience stores, grocery stores, and other businesses that sell Coca-Cola to the general public. To ensure that manufactured beverages do not travel far to reach its consumers, Coca-Cola’s distribution system was developed in such a way that products were made locally to markets where they are being sold.

Typically, final Coca-Cola beverages are distributed within a hundred-mile radius. This is done to ensure an efficient response to customers’ needs and changes in demand, which are closely associated with the taste of local consumers. Thus, as Coca-Cola bottlers manufacture the final product, they use their own logistics channels to deliver beverages to several categories of customers. These customers include wholesalers, retail stores (i.e., groceries, supermarkets, corner shops, etc.), restaurants, cafes, and nightclubs, petrol stations, and vending machine businesses (Lu and Tiwana, 2015). This means that Coca-Cola does not pay for all distribution expenses and is only concerned with delivering the syrup and other supplies to manufacturers and bottlers, which then distribute the final product. Overall, the Coca-Cola Company saves costs for beverage distribution and can target them in marketing efforts or other processes that enhance the operations of the company. Taking into consideration the fact that the Coca-Cola Company is not directly involved in all processes associated with product distribution, there is a problem of the lack of internal communication and customer loyalty, which require addressing.

Operations Management

SWOT Analysis

In order to analyse Coca-Cola’s operations management and identify whether it is effective for meeting consumers’ demands, it is important to first conduct a brief SWOt analysis. It will help the discussion because of its usefulness in identifying trends and threats that the company should address. In terms of the company’s strengths, brand awareness and robust distribution network are primary advantages on which Coca-Cola builds its operations. Being the most recognisable beverage brand in the world, with a distinct message and a signature logo, Coca-Cola uses its popularity to push its both traditional and unique beverage flavors. In order to make Cola and other drinks available to consumers in two hundred countries worldwide, the company developed a unique distribution network that utilises Coca-Cola “owned or controlled distributors, as well as independent bottlers, wholesalers, and retailers” within a diverse operations network (DeFranco, 2015, para. 7).

With regards to Coca-Cola weaknesses, the company is challenged by inefficient water management as well as fluctuations in foreign currencies. Water is a limited resource that makes up the largest portion of all ingredients used in Coca-Cola production, and the rising demand for it creates extra expenses as well as contributes to unethical practices. Also, due to the global scale of operations, the company earns revenues in different currencies, which means that it has to translate all revenues into U.S. dollars. Weaknesses in currencies inevitably offset financial strengths. In order to address the challenges, Coca-Cola can use such opportunities as diversification and extended reach to its advantage. However, it is essential to address such threats as indirect competition (e.g., Starbucks and Dunking’ Brands Group) since they provide substitutes for traditional products that Coca-Cola offers (DeFranco, 2015). There is a significant problem of customers gravitating toward customisable options for beverages, which should be addressed by Coca-Cola’s operations management.

Operations Management Process

The process of operations management is associated with the Coca-Cola Company making sure that its business operations are efficient in terms of the use of resources and effective concerning meeting the demands of its customers. A typical day at Coca-Cola operations starts with the employees at warehouses filling sales orders from the previous day and managing the logistics process by placing the required amount of beverages on trucks that then deliver products to customers. In Europe and the United Kingdom, where the systems of delivery may differ from one region to another, warehouses usually load their distribution trucks for completing bulk delivery to the warehouses of their customers rather than to stores directly.

At the same time when trucks are being loaded with beverages, sales managers, merchandisers, and account representatives across Coca-Cola plan their efforts for the day and negotiate sales opportunities to ensure an efficient operations management. Then, delivery drivers that operate on a local scale make sure that each vehicle is loaded correctly and that every destination is fulfilled. In terms of sales personnel’s operations, employees organise their calls, handle necessary paperwork, and communicate with their customers.

Throughout the day of operations, the production lines of Coca-Cola beverages continue working, ensuring that the bottling line fulfills the necessary number of orders. Some bottling lines, predominantly those that serve large cities, operate twenty-four hours each day; however, the rest work up to twenty hours. The continuous production of Coca-Cola beverages ensures that final products are as fresh as possible as well as that inventories are kept to a minimum. In general, Coca-Cola warehouses in Europe and North America turn over their complete inventory in a week (NPLAN, 2012).

As beverages are delivered to customers, drivers record their deliveries in order to reconcile their operations at the end of each day. Both in Europe and North America, Coca-Cola merchandisers work inside stores to ensure that products are displayed in a way that will be attractive to consumers. At the same time, account managers work with Coca-Cola customers to receive new orders, keep track of the sales cycle, and keep product delivery moving forward. It is also important to mention that Coca-Cola’s operations management is closely associated with the efficient performance of Information Systems employees responsible for ensuring the availability of operating and sales data to managers and other relevant personnel within the period of twenty-four hours.

A quick dissemination of information is necessary for making it easier for managers and other administrative personnel to provide employees with the tools they need for making their operations effective. An example of information use within the operations management framework includes the creation of marketing strategies and programs for promoting Coca-Cola beverages, the coaching and training of personnel, as well as leadership initiatives for ensuring that operations management is led by effective leaders.

As an aspect of operations management, it is important to mention Total Quality Management (TQM) implemented at Coca-Cola. The company conducts continuous inspections throughout the entire process of beverage manufacturing to ensure that customers receive final products of the same high quality on a consistent basis. Inspections usually imply the implementation of corrective actions based on the identification of existing problems. Coca-Cola has introduced its inspection methods into the existing standards of quality and reducing the instances of product recalls associated with poor quality. Quality control and quality assurance are both used as supplementing processes within TQM. While the former is used for controlling the quality of the production line within Coca-Cola manufacturing, the latter is concerned with monitoring the entire process of operations, including addressing important problems at high speed. The continuously-updated Coca-Cola database allows quality managers to enter relevant data and monitor the progress of quality improvement updates.

Lean Operations

Based on the evaluation of the supply management processes at Coca-Cola, it can be concluded that the company is on its way to establishing a framework of completely lean operations. To ensure the success of such operations, Coca-Cola designs new structures, systems, and skills for building new models that align with behaviors necessary solving problems that arise on a regular basis. Another characteristic of lean operations as evidenced by Coca-Cola is starting with identifying problems in its operations management rather than with ideas. According to Butler (2014) for Coca-Cola Journey, the company always starts its improvements with deciding what challenges it faces regularly and then linking them to larger problems within a big market. This way of thinking about problems helps the company ensure that the value of chosen solutions flow back to Coca-Cola as well as creates potential business opportunities for partners.

In Coca-Cola’s supply chain, the use of minimum viable products for learning and improving is another characteristic of lean operations. Minimum viable products are fully designed and executed and represent the cheapest, most viable solutions for delivering high quality and the best value to end users – consumers. The use of minimum viable products is quite different from the usual processes of product development that the majority of large companies use. Traditionally, other big companies follow the “stage-gate” process that starts with the generation of ideas and ends with launching a product on the market. However, Coca-Cola’s approach is lean and is similar to how startups operate – they introduce new products to the market and make changes based on learning. In this way, the company does not waste valuable resources and quickly understands what works and what does not based on customers’ feedback (Butler, 2014).

Within the context of lean operations, Coca-Cola focuses on only those metrics that matter. This approach to data measurement is not new to large companies because in wide-scale operations, focusing on the most important aspects of business measurement is the only way to get companies moving forward. For example, Coca-Cola focuses on measuring the number of beverage bottles sold every day to adjust its supply of products based on the demand. Vital performance indicators allow Coca-Cola to create an extreme focus and clarity for the entire team (Butler, 2014).

Recommendations

In order to supplement the analysis of Coca-Cola’s supply and operations management, recommendations for improvement will be provided. A crucial step in addressing existing problems is improving Coca-Cola’s water management processes. At the moment, the company reports collaborating with 2030 Water Resources Group (2030 WRG) to improve water policies in countries such as China, India, Mexico, Kenya, South Africa, Peru, and several others (Coca-Cola, 2017). However, long-term goals are usually complex because the company is unable to see immediate results from its actions. It is recommended for Coca-Cola to invest in close collaboration with local communities and governments that experience the direct effects of water depletion in their areas. Coca-cola should measure its water use ratio twice a year to see whether it is decreasing, monitor the compliance of its manufacturing facilities with the standards of internal wastewater treatment, as well as measure the percentage of replenished water (Coca-Cola Hellenic, 2016).

Another recommendation associated with improving Coca-Cola’s supply chain management is to strengthen the communication between partners. Due to the international operations of Coca-Cola, it is advised to set a specific plan of strategic communication to ensure that branch offices, bottlers, transportation facilities, and other parties involved in the supply chain communicate effectively. Also, it is suggested that all relevant stakeholders should be on the same page in terms of the company’s vision and mission. In addition, it is always a good idea to adapt communication vehicles to cater to the needs of different partners worldwide (European Commission, 2017).

Overall, water sustainability and the unification of partners’ efforts are the two most important areas for improvement at Coca-Cola supply chains. Since the supply chain and operations management procedures that the company has implemented are successful enough to bring revenue and ensure competitiveness in the market, optimising sustainability efforts and ensuring that all partners have the same communication practices that lead to their improved collaboration. Because of the unique position of Coca-Cola Company in its supply chain, it can act as a mediator in the relationships between its second and first-tier suppliers, manufacturers, bottlers, and final customers.

Reference List

Butler, D. (2014). Learning to be lean: 5 lessons Coca-Cola has learned about building startups. Web.

Coca-Cola (2012). Offices & bottling plants. Web.

Coca-Cola (2016). Product description. Web.

Coca-Cola (2017). Our partners: 2030 Water Resources Group. Web.

Coca-Cola Hellenic (no date). Supply chain overview. Web.

Coca-Cola Hellenic (2016). Sustainability update: Water stewardship. Web.

CSI Market (2018a). Coca-Cola Co’s suppliers performance. Web.

CSI Market (2018b) Coca-Cola Company suppliers by industry. Web.

DeFranco, K. (2015) The Coca-Cola Company: A short SWOT analysis. Web.

European Commission (2017). Joint communication on “A strategic approach to resilience in the EU’s external action”. Web.

Lu, L. and Tiwana, S. (2015). The Coca-Cola Company’s distribution strategy. Web.

NPLAN (2012). Breaking down the chain: A guide to the soft drink industry. Web.

Sapardanis, C. (no date). Coca-Cola supply chain management success story. Web.

Thorpe, L. (2011). Coca-Cola – Replenishing water in the drinks industry. The Guardian. Web.

White, G. (2015). From factory to fridge: Inside Coca-Cola’s supply chain. Web.